Here’s an overview of the Best Soldering Mat that we’ll explore today:

Soldering mats are essential workbench accessories for electronics repair and DIY, offering heat resistance, part organization, and protection for delicate surfaces. With a range of sizes, features, and price points, choosing the right mat can impact efficiency, safety, and outcome quality. In this review, I test and compare five mats from STREBITO, PAFOWO, and Kaisi to evaluate heat tolerance, organization capabilities, durability, and user experience. My methodology combines surface-level feature checks (temperature rating, magnetic zones, and built-in rulers) with practical use scenarios: micro-soldering on smartphones, assembling PCBs, and handling small screws and tools. Each product is assessed on build quality, usability, and value relative to price.

1. Kaisi S-130 Insulation Silicone Soldering Mat Repair Mat

- Brand: Kaisi

- Manufacturer: Kaisi

The Kaisi S-130 is a compact insulation silicone mat designed for small to medium-sized repair work. Its standout feature is the built-in scale ruler (0 ~ 25 cm), 124 screw positions, and 8 notches, which helps organize tiny components during disassembly and reassembly. The mat is rated to withstand temperatures up to 932°F (500°C), providing direct-solder capability without a separate soldering surface, and its silicone surface is described as anti-slip and anti-scratch to prevent movement during work.

In practice, the S-130 excels for cellphone and small gadget repairs where space is constrained. The non-magnetic, non-deforming surface reduces risk to precision parts, and the 0.14-inch-thick mat provides a stable platform for fingertip work. The two-year warranty and 90-day refund window accompany a strong value proposition at a budget price. However, the lack of built-in magnetic zones means there is no dedicated magnetic area for screws, which can slow down workflows that rely on quick-part placement. Cleaning and edge protection are good, but the compact surface may feel cramped for larger assemblies.

Pros

- Built-in scale ruler and screw positions improve part organization

- High temperature resistance up to 932°F (500°C)

- Non-slip, anti-scratch surface prevents movement

- Compact size suitable for small repairs

- 2-year warranty and solid customer support

Cons

- No magnetic zones, which limits part retention

- Small footprint may be limiting for larger projects

- No anti-static protection specified

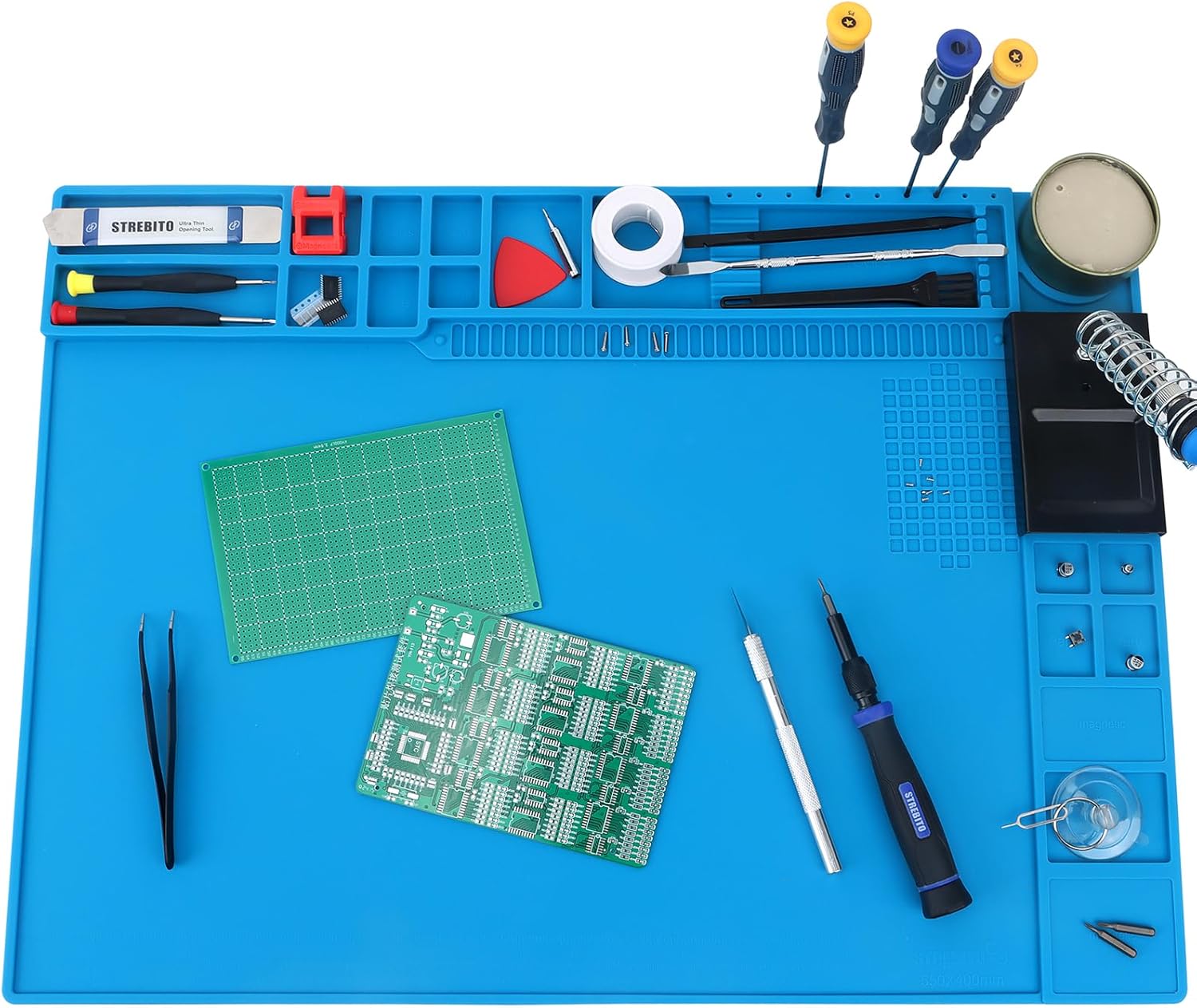

2. STREBITO Soldering Mat – Large

- Brand: STREBITO

- Manufacturer: STREBITO

The STREBITO Large mat is a feature-rich, magnetic work surface with 17 accessory zones, 10 screwdriver slots, 1 tool zone, and 133 screw compartments. It adds three magnetic areas to hold metal components and screws, making it ideal for tablet, laptop, PC builds, and multi-part repairs. The surface is heat resistant to 932°F, and the mat is designed to be non-scratch with raised edges to prevent parts from rolling off. The large 21.7″ x 15.8″ footprint provides ample space for more expansive projects, and it includes built-in metric and imperial rulers for precise measurements.

Practically, this mat shines when you’re juggling many small parts across mid-to-large electronics projects. The magnetic zones simplify part retention during disassembly and reassembly, while the easy-to-clean silicone surface resists corrosion. It’s not an anti-static mat, so for sensitive ESD devices you should pair it with an anti-static strap and allow static to dissipate. The main trade-offs are its higher price point versus compact mats and the lack of true anti-static properties, which could be a concern for certain components like memory modules or high-precision boards.

Pros

- Extensive organizational zones and magnetic areas

- Large working surface suitable for laptops and PCBs

- High heat resistance up to 932°F

- Non-slip surface with raised edges

- Easy to clean and store (fold/roll)

Cons

- Not an anti-static mat; requires ESD precautions

- Higher price point relative to compact mats

- Magnetic fields may affect sensitive components if not managed

3. STREBITO Soldering Mat Large

- Brand: STREBITO

- Manufacturer: STREBITO

This STREBITO Large Black variant matches the features of the standard large mat but uses a color option that can reduce glare and hide stains. It maintains the same 17 accessory zones, 10 screwdriver slots, 133 compartments, and three magnetic areas. The temperature rating is 932°F, and the included construction is designed for robust, long-term use with a durable, elastic silicone compound that resists deformation when folded or rolled for storage.

From a usability perspective, the Black version provides the same wide-ranging organization benefits as its counterpart, with the same caveat about ESD. It’s a strong choice for users who need a spacious workspace and magnetic retention for screws and tools, such as RC hobbyists or PC builders. The consistent features across colorways mean dependable performance, but keep in mind similar limitations in static-sensitive scenarios and potential magnetic interference with very small, high-precision components.

Pros

- Very large work area with extensive organization zones

- Magnetic and non-magnetic areas protect/sort components

- High heat resistance and durable silicone

- Foldable/rollable for easy storage

- Clear measurement scales (metric/imperial)

Cons

- Not anti-static; requires ESD measures

- Higher price point vs compact mats

- Magnetic fields could interfere with small ferrous parts if misused

4. STREBITO Soldering Mat Electronics Repair Mat

- Brand: STREBITO

- Manufacturer: STREBITO

The 13.8″ x 9.9″ STREBITO mat offers a mid-sized option with 7 accessory zones, 1 tool zone, 3 magnetic areas, and 70 compartments. It emphasizes a balance between portability and organizational capability, with temperature tolerance up to 932°F and a silicone surface designed to resist scratches and corrosion. The dual-sided non-slip surface and raised edges help keep items in place during soldering and reassembly.

In use, this mat suits small to mid-size repair tasks—watch repairs, phones, small gadgets, and accessory-heavy projects. The reduced footprint makes it easy to transport or tuck into a workstation with limited space. However, the smaller number of zones (vs the large STREBITO mats) means it offers less granular organization for screws and parts, which can slow you down on complex assemblies. As with all silicone mats in this category, expect the need for external ESD practices for static-sensitive components.

Pros

- Compact size improves portability and storage

- Magnetic zones aid in part retention

- Good balance of zones for smaller projects

- High heat resistance to 932°F

- Durable, easy-to-clean silicone surface

Cons

- Fewer organization zones than larger STREBITO mats

- Not an anti-static mat; relies on external ESD measures

- Smaller workspace may constrain larger repairs

5. Premium Heat Resistant 932°F Silicone Soldering Mat

- Brand: PAFOWO

- Manufacturer: PAFOWO

PAFOWO’s mat combines generous real estate with an anti-static claim, which is notable in this category. The large surface (17.7″ x 11.8″) is topped with 3 part boxes with covers, 4 magnetic areas, 124 screw positions, 42 spare units, and 15 notches. It also provides a built-in scale ruler (0~36 cm) and is rated for 932°F, making it a versatile choice for phones, laptops, and chassis work. The material composition includes anti-static properties, which can be appealing for static-sensitive components when used correctly.

From a usability standpoint, the mat’s organization system allows quick sorting and access to parts during complex repairs. The anti-static claim is a plus, but the user should still pair it with proper static-dissipation practices (e.g., wrist strap) for maximum protection. The mat’s weight and rigidity are acceptable for desktop use, and cleaning is straightforward with soap and water or alcohol. The main caveat is the claim of anti-static properties in a silicone mat; for critical ESD-sensitive components, consumers should verify lab-grade ESD compliance or testing data if that is a priority.

Pros

- Anti-static claim adds value for sensitive components

- Large surface with extensive organizational features

- Multiple screw compartments and part boxes

- Temperature resistance up to 932°F

- Scale ruler and notches aid precise work

Cons

- Anti-static claim may require verification

- Not magnetic in all zones; mixed zone strategy can complicate workflow

- Color/material may show stains over time depending on use

Frequently Asked Questions

We’ve compiled answers to the most common questions about soldering mats to help you make an informed decision.

Conclusion

.

.

Final thoughts here.